The dominant culture: Yogurt for the masses

Contributing Editor, Food Product Design

For at least 4,000 years, people in various parts of the world have been making and eating yogurt. In the early 20th century, Nobel-prize winning Ilya Metchnikoff began studying how yogurt's lactic-acid-producing bacteria might increase human longevity. Thanks in part to his research, more than 30% of the world's population now eats yogurt regularly, and worldwide per-capita consumption is estimated at 4.3 lbs. per year.

For at least 4,000 years, people in various parts of the world have been making and eating yogurt. In the early 20th century, Nobel-prize winning Ilya Metchnikoff began studying how yogurt's lactic-acid-producing bacteria might increase human longevity. Thanks in part to his research, more than 30% of the world's population now eats yogurt regularly, and worldwide per-capita consumption is estimated at 4.3 lbs. per year.

Yogurt is a calcium powerhouse and a source of high-quality protein; since manufacturers often add nonfat dry milk (NFDM) to their formulations, ounce for ounce, yogurt generally contains more calcium and protein than milk. Don't forget its riboflavin, phosphorus, magnesium, niacin and vitamin B12, too.

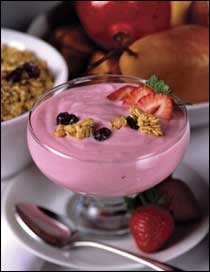

During the 1960s and 1970s, consumers considered yogurt the stock-in-trade of the health-food and weight-watching markets. But these days, with sumptuous dessert-like flavors, such as mocha cappuccino, New York cheesecake and Key lime pie; with texture options running from drinkable liquids to decadent custard-style confections; and with fun delivery options like squeeze tubes and yogurt mix-in "kits," yogurt's mass-market appeal makes sense. Between 1978 and 1998, yogurt consumption more than doubled from 2.5 to 5.1 lbs. per capita, and from spring 1999 to spring 2000, sales of the dairy treat rose 8.1%, claims Dairy Field.

The basics of yogurt manufacture have remained more or less the same since the good old days: a mixture of lactic acid bacteria ferments milk's lactose to lower its pH, thus coagulating some of the milk proteins into a tart, creamy curd and letting the rest separate out as a liquid whey.

That's not to say that the light of technology hasn't shined upon yogurt production. These include new ingredient options in stabilizers and texture enhancers, sweeteners, flavors, and, particularly, bacterial cultures.

The culture club

Yogurt simply wouldn't be yogurt without Lactobacillus bulgaricus and Streptococcus thermophilus. The FDA standard of identity legally requires manufacturers to use at least those two cultures to label their product yogurt. Then, there's the bacteria's transformative effect on milk, fermenting dairy-sugar lactose to lactic acid and lowering the pH so that casein proteins coagulate into viscous gels. With a little help from stabilizers and other ingredients, these gels become what we know as yogurt. According to Marilyn Stieve, marketing manager for fermented milk products, Chr. Hansen North America, Milwaukee, the bacterial cultures also produce polysaccharides that enhance the yogurt's texture, as well as compounds such as acetaldehyde that, combined with lactic acid's tartness, create that characteristic yogurt flavor.

What do cultures do for the health of the yogurt eater? Researchers studying the effects of probiotics — beneficial bacteria naturally present in the intestinal tract — are finding exciting answers to that question. While L. bulgaricus and S. thermophilus aren't known to be probiotic themselves, other yogurt cultures exhibit marked health effects and thus are in higher demand as probiotics in yogurt mixes. Specifically, L. acidophilus, L. reuteri and Bifidobacteria participate in competitive inhibition in the human intestinal tract, whereby they beat out "bad," possibly pathogenic microorganisms for nutrients and space. Combine this action with the ability of probiotic bacteria to survive the journey from the factory to the human gut (a trek that L. bulgaricus and S. thermophilus don't always survive), and you see the healthful possibilities of probiotics.

Researchers also are elucidating how bacterial competitive inhibition enhances the immune response, as well as how it may reduce cholesterol levels in people who consume certain quantities of the cultures. L. reuteri potentially inhibits E. coli, Salmonella, Listeria and Staphylococcus bacteria, as well as the yeast Candida, via one of its metabolic intermediate compounds, reuterin. Another L. reuteri metabolic byproduct, conjugated linoleic acid, has exhibited chemoprotectant effects in some studies, too. Some Lactobacillus-containing products may help prevent colon cancer by lowering the concentration of intestinal procarcinogens or reducing the level of the enzyme that converts procarcinogens to carcinogens. Auxiliary compounds produced during Lactobacillus and Streptococcus fermentation show promise as potential antimutagens. Mechanisms aren't yet known, but the demonstrated effects ensure that researchers will keep trying to pin them down.

The main reason for probiotics' healthful reputation traces back to their effects on digestion and intestinal well-being. They out-compete the microbes that cause diarrhea, thus helping prevent this widespread problem. As a boon to individuals who have some difficulty digesting lactose, all common yogurt cultures — both probiotic and non — are adept at splitting.

Fun with fermentation

There's a wide gap between dumping crafty cultures into milk and winding up with a tasty, texturally pleasing, healthful yogurt. Manufacturers usually obtain the chosen cultures as frozen direct vat-set pellets, although Stieve notes that freeze-dried cultures also are available. Frigid temperatures ensure that the cultures arrive at the plant alive and ready to ferment. "Freeze-drying doesn't hurt them, and deep-frozen, they love. We store our cultures at -85ºC," notes Stieve. She recommends that yogurt manufacturers store the cultures in -45ºC freezers.

Processors introduce the culture pellets into the "white mass" — typically, a pasteurized blend of NFDM, stabilizers and sugar that's been cooled to around 45ºC post-pasteurization. Were they to go in prior to pasteurization, the high heat would kill them. (Notice also the absence of flavors; alcohol and other components of flavor systems can inhibit and even kill certain cultures. For that reason, fermenting the white mass first and then blending in flavors is best.)

Fermentation of stirred, or European-style, yogurt, which has a blended, creamy texture, occurs in large tanks. After fermentation, manufacturers safely meter in flavors, and then fill the cups. In the case of the firmer yogurt variety known as cup-set, or fruit-on-the-bottom, manufacturers first discharge a flavor and fruit preparation into the bottom of the cup, then top with the white mass mixed with cultures. The cups then enter an incubation room for fermentation.

To tell processors that fermentation has run its course, the most important benchmark is pH. They normally pull the yogurt from fermentation to cool at around pH 4.6 to 4.7. Brookfield viscometer measurements also indicate whether fermentation has produced the desired texture. The amount of time required varies with the culture used. "It can go anywhere from three to four hours, all the way up to eight or nine hours," Stieve notes. Alternatively, yogurt makers can turn to new, fast-fermenting strains of cultures.

Other new technologies include cultures that modify yogurt texture in specific ways, reducing dependency on texturizers while yielding a unique mouthfeel. The thickening cultures, usually strains of L. bulgaricus, produce more polysaccharides during fermentation, creating a creamier, more viscous yogurt. Bypassing heavy doses of stabilizers, Stieve notes, allows yogurt's flavors to shine without a starchy or gummy taste.

These fancy cultures don't solve all yogurt-processing pitfalls, however. Manufacturers must look out for classic defects, such as post-acidification. Generally, manufacturers begin cooling a newly fermented yogurt to halt fermentation and acidification when the pH drops to about 4.6. However, the cultures in a yogurt mix continue producing some acid even after cooling, pushing the pH down to about 3.8. This results in excessive tartness and unappealing wheying-off at the surface.

Fortunately, Stieve says, "culture manufacturers have come quite a long way in selecting cultures that have minimal post-acidification." In fact, emerging trends have steered culture development toward strains that contribute milder flavors in general, which makes sense given the sensitive palates of children. Manufacturers can manipulate yogurt flavor to a large extent purely through informed culture choice — creating flavors ranging from the mild, almost ice-cream-like profile children prefer to the stronger, more acidic "Old World"-style characteristic of traditional Eastern European yogurt.

Processors also can forestall post-acidification by paying strict attention to the speed of cooling. The goal is to cool it well within five minutes of reaching the ideal pH and viscosity.

Once manufacturers send the finished yogurt into storage, they still want to make sure that, by the time the consumer gets it, those live and active cultures are still…well, live and active. But, there's no tally of colony-forming units (cfu) on a yogurt label next to the fat grams. The United States has no legal minimum for the concentration of live and active cultures a yogurt must contain. Stieve says that some countries do have such laws, and they usually specify a lower limit of 10 million L. bulgaricus and S. thermophilus cfu per ml.

To indicate that yogurt contains "live and active cultures," the carton may carry a "LAC" designation. This labeling system, developed by the National Yogurt Association, McLean, VA, means that the yogurt's cultures are alive and kicking, and that the yogurt contained at least 100 million cfu per gram at production, and under normal refrigeration and handling it should have at least 10 million cfu per gram at consumption.

The concentration that ultimately perishes depends on pH, formula, sugar levels and storage quality, among other factors. Stieve notes that losses of 50% to 90% aren't unheard of, particularly in formulas heavy in sugar or highly acidic systems. To ensure products deliver adequate culture levels, manufacturers should boost the amount introduced into the mix.

Product medley

Product medley

Do frozen yogurts contain live and active cultures? Are they even yogurts? If they call themselves yogurt, they must be, but the resemblance to the traditional fermented product can stretch that identity pretty thin. Some manufacturers will actually ferment the base, making a real, live yogurt. Or some take unfermented ice-cream base and add L. bulgaricus and S. thermophilus cultures before freezing so they can call the product yogurt.

The popularity of alternatives to traditional yogurt, such as squeezable and drinkable versions, has grown in recent years. Not surprisingly, culture considerations faced for these products differ from those in traditional yogurt making. Drinkable yogurts require cultures that produce enough polysaccharides to give a body richer than that of flavored milk, but not so much that the yogurt isn't liquid. The polysaccharides also help diminish graininess, as well as the sliminess, or "ropiness," that sometimes plagues yogurt. Portable squeeze yogurts have a texture somewhere between traditional and liquid yogurts. Their highly stabilized nature helps maintain that texture; combining stabilizers with the improper culture choice can further exacerbate ropiness.

Milking it

Obviously, cultures need something to ferment, and milk, with plenty of lactose, makes the perfect choice. However, all the other elements — protein, fat, minerals and dairy solids — as well as cultures and processing conditions, must come under consideration when making yogurt.

Milk proteins — particularly casein — gel and coagulate under fermentation's acidic conditions to yield the basic structure. Tony McCarthy, senior research and development manager, Glanbia Food Ingredients, Ballyragget, County Kilkenny, Ireland, says casein levels "may be affected by seasonality, as the ratio of whey to casein and the level of plasmin — an enzyme capable of breaking down the casein — may vary during stage of lactation."

Whey proteins play a few roles, too. When the whey protein beta lactoglobulin interacts with casein by way of a thiol-disulfide exchange, the casein-to-casein gel is modified, creating a smoother texture. If that gel gets too strong, it causes syneresis and a texture resembling cottage cheese. "Furthermore, gels formed during pasteurization tend to be broken up by subsequent pumping and stirring, and therefore, don't contribute much to the final texture or, even worse, may contribute a chalky, gritty mouthfeel," McCarthy warns. Few things do more to improve yogurt's mouthfeel than a liberal smattering of dairy fat — the more, the creamier. But catering to the desires of health-conscious consumers makes high fat levels somewhat taboo. McCarthy suggests getting more mileage from milk fat by passing the mix through a single-stage homogenization rather than the more common double-stage to promote a degree of fat aggregation that boosts texture, viscosity and mouthfeel.

Minerals in milk, and NFDM also affect texture. To give the white mass an extra measure of casein, and thus viscosity, producers commonly add NFDM. But NFDM's relatively high mineral load can cancel out the textural benefit of the extra protein, and also can lead to a powdery or chalky mouthfeel. Minerals have their own flavors too, many of which (particularly acidic and metallic ones) aren't welcome in yogurts.

Yogurt producers usually first standardize the milk to a desired fat content before adding the other ingredients to the white mass. Then comes pasteurization at a variety of time/temperature combinations, with a common treatment at around 195°F for 10 minutes. McCarthy notes that this rather severe heating step can cause the kappa and beta casein proteins to partially disassociate from the casein micelle, leaving behind a "skeleton" rich in alpha casein. "This ‘skeleton' micelle is much less stable than the native micelle and tends to aggregate in a linear, or thin, filamentary manner during fermentation and acidification. As fermentation proceeds, the disassociated casein molecules — with or without bound whey proteins — then come home to roost and re-associate with the casein filament, reinforcing it and strengthening it," he says. It's an "intricate dance" of proteins that gets some choreographic help from the ionic environment, and it all contributes to what we know as yogurt.

Then comes homogenization; a combination of 500 psi in the second stage and 1,500 psi in the first for a total pressure of 2,000 psi is typical. In addition to fully blending the ingredients, homogenization prevents wheying-off during fermentation and storage and, in general, enhances stability. Following this step comes cooling to incubation temperature, inoculation and incubation. The subsequent processing steps, such as addition of fruit and flavor preparations, stirring and packing, can negatively impact texture. McCarthy lists a few processing techniques to maximize yogurt's viscosity: damage the initial structure as little as possible; allow the casein network to "heal," or "recover," for a while after stirring or pumping; and, if possible, partially delay casein-network formation until after stirring or pumping.

A stable foundation

Without stabilization, the creamy curds and liquid whey in yogurt tend to separate. While this can be remedied with a good stir, a pool of whey turns off some consumers. Thus, yogurt makers manipulate texture and extend their products' shelf life with stabilizers. According to Valerie Jezequel, technical service supervisor, National Starch and Chemical Company, Bridgewater, NJ, probably the most common U.S. yogurt-stabilizer combination consists of a starch and gelatin team, but the options include an array of starches, hydrocolloids and emulsifiers.

"Each situation demands a different stabilizer solution," says Jon Hopkinson, Ph.D., project leader of dairy and frozen desserts, Danisco Cultor, New Century, KS. "There are an infinite number of potential textures in yogurt, from hard balls of dried yogurt like those found in India to water-thin drinking yogurts. For these, there are multiple stabilizer systems that will work. Choosing the proper one requires a close relationship between the developer and his stabilizer supplier."

Regardless of the chosen stabilizers, yogurt manufacturers strive for thick and creamy textures with minimal syneresis, an attractive sheen (particularly attainable via gelatin and pectins) and a sturdy set.

|

Cooking out a starch-based stabilizer to its full gelatinization temperature prevents a number of quality defects. Fully swollen molecules have the optimum water-holding capacity that enhances yogurt's texture and prevents syneresis. To ensure starch gelatinization before fermentation, yogurt manufacturers must take into account preheating and pasteurization temperatures. Additionally, instant starches build viscosity immediately in the cold mix, deterring heat transfer during pasteurization and, because of the early swelling, shearing more easily during homogenization.

When selecting a stabilizer system, consider homogenization pressures, too. This step — particularly in higher-fat yogurts, which require higher pressures — imparts considerable shear to the starch granules. If those granules are fully swollen, they may fragment and lose their granular integrity, and thus their optimal functionality.

In general, native cornstarches or waxy maize starches don't have the structural tolerance to stand up to yogurt processing. Modifying them with cross-linking strengthens the granules and builds in heat and shear tolerance. Substitution confers cold-temperature stability on products by preventing starch retrogradation, which is less critical in yogurts. It does, however, enhance mouthfeel. "If customers have in mind a really creamy mouthfeel with a heavy mouth-coat, stabilized starches can help deliver this type of texture," Jezequel says. In addition, new physically modified cornstarches might fit the bill for those looking for an "all natural" label.

Still, some consumers complain of a lingering starchy texture or aftertaste. Thanks to their cleaner flavor release and blander overall flavor, tapioca starches come in handy in these situations. Tapioca starches have a naturally lower hot viscosity, so, if homogenization post-pasteurization is needed, a highly cross-linked tapioca starch will be less susceptible to shear damage.

Yogurt producers must pay mind to potential interactions between stabilizers and other ingredients. "Many stabilizers interact with the proteins in milk because both the proteins and the stabilizers contain charged residues," says Hopkinson. "During the manufacture of yogurt, the pH goes below the isoelectric point of casein. This means that the net charge of the casein protein changes from negative to positive." Depending on the stage of the yogurt-making process, this means stabilizers may be attracted, repelled or ignored by the proteins.

With the relatively low sugar percentages found in white-mass formulations, Jezequel says there's little need to worry about sugars out-competing starches for water of hydration. That's not the case in high-sugar fruit and flavor preparations. In that situation, a starch needs to be fully hydrated and functional to contribute a smooth, short and spoonable texture with attractive clarity and sheen — a task for which waxy maize starches are well-suited.

Aside from these basic requirements, the two general categories of fruit and flavor preparations — fruit-on-the-bottom and stirred preps — carry their own stabilization considerations. Fruit-on-the-bottom preps must maintain cohesion even after depositing the white mass, as well as prevent color migration from the prep into the yogurt. The stabilizer also must overcome water migration. "It's important that water not migrate into the fruit and cause it to become watery," Hopkinson notes. "In the yogurt, it's also important to prevent water from leaving and thus causing an increase in the calcium ion concentration at the interface." This creates an undesirable "hard" layer at the boundary. Pectins have traditionally kept these deleterious interactions under check.

Stabilizers for stirred yogurts help keep smaller, dispersed fruit pieces suspended throughout the fermentation tank so that each cup contains the expected concentration of fruit pieces. But the stabilizer must balance the fine line between suspending fruit and displaying proper flow behavior. Fruit and flavor preps for stirred yogurts enter the white mass following fermentation, allowing processors leeway in choosing types and levels of stabilizers that, in other cases, may slow down fermentation or hinder yogurt texture development.

|

In elementary school, class would stop each day for a 20-minute "nutrition break." Yogurt and granola bars were encouraged and soon enough, these two came together in the form of yogurt-coated granola bars. A shell of yogurt has gone on to coat a number of other products as well, providing an extra dimension of flavor and nutritional clout. |

| According to Rachel Gustafson, applications and development manager of cheese and dairy flavorings, Kerry Ingredients, Beloit, WI, the coatings use a spray-dried powder that starts with real yogurt. The type depends on the coating's application and characteristics. "The yogurt is basically a building block," Gustafson says. "Most customers, because they need to dry a good volume of product to make it worthwhile, start with the base material with the widest application." Hence, the typical use of plain, unflavored yogurt. Gustafson notes that nonfat yogurt tends to be most common. Powder manufacturers also make spray-dried yogurt made with whole or 2% milk, to increase perception of richness. The powders are blended with vegetable fats to make the coating anyway, and due to economics, nonfat yogurt powders predominate. Yogurt-powder manufacturers need not include sugar or stabilizers, Gustafson says. Sugars come later in the manufacturing process, and texture maintenance from stabilizers is a moot point. Processors can spray-dry the yogurt base cold (unpasteurized, although the milk used is always pasteurized) to keep the yogurt's cultures viable, or pasteurize the yogurt prior to spray-drying as a final kill step. Either way, it's still a legitimate yogurt powder. Once manufacturers have turned yogurt into a powder, notes Diane Carnell, application and development manager at Kerry's facility in New Century, KS, they refine it with vegetable fat — usually palm kernel oil — and sugar via a process very similar to chocolate processing to get a very fine, smooth blend. For health-oriented consumers, manufacturers can use fractionated palm kernel oils (they're less expensive and have the viscosifying effect that the coatings need) for a cleaner label claim. And since a coating can have up to 30% fat, making that fat less of a health liability can make a big difference in a health-food product. Ratios of yogurt, fat and sugar fluctuate with the application, and Carnell notes that unless a manufacturer is going after a niche market, the yogurt level will probably be on the low end of the scale. The fat level tends to have the most pronounced effect on viscosity, so a panning or enrobing application that needs a firm coating should include a relatively high fat level. Tilting the fat proportion downward to reduce viscosity results in a mixture applicable for use as a yogurt baking-chip. |

Pectin, a popular fruit and flavor prep stabilizer because of its reputation as a natural product, contributes to the prep's viscosity and aids in fruit suspension in stirred applications. Pectin is a popular stabilizer in the white mass, as well. Because pectin carries a negative charge at low pH levels and casein proteins a net positive charge, the two form ionic bonds directly with each other at the pH levels typical in yogurt. This helps stabilize the yogurt and is particularly important in yogurt drinks. Pectin also interacts with the calcium, as Hopkinson explains: "Pectin, like many hydrocolloids in nature, contains charged sites along its chain. For pectin, these charges are negative at the pH levels typical of foods. Calcium ions have two positive charges. Because of this, calcium can form a bridge between negatively charged sites on pectin and other polymers like protein."

Different types of pectin — low-methoxy, high-methoxy and amidated, for example — behave differently in these situations. They also exhibit different sensitivities calcium. "The higher the degree of esterification, the lower the calcium reactivity and the higher the amount of protein interaction at low pH (generally from around 3.8 to 4.2)," says Hopkinson. And not only the amount, but the distribution of methoxyl groups on the pectin chain affects its functionality. Thus, some high-methoxy pectins work well in drinkable yogurts, whereas others don't, with a pectin's structure as well as the extent of its substitution influencing functionality. As for the yogurt's white mass, Hopkinson advises that mid-range-to low-methoxy pectins work best.

Locust bean gum helps increase viscosity in yogurt systems and fruit and flavor preps and sometimes serves as the primary stabilizer in frozen yogurts. Carrageenan also offers significant stabilization opportunities for the fruit prep manufacturer, suspending fruit pieces while maintaining a viscosity compatible with most metering equipment. But, when using carrageenan in fruit preps, Hopkinson notes that the product developer must be careful to keep optimum ion concentrations in the system to prevent negative interactions with the yogurt. Furthermore, carrageenan's acid stability at high temperatures comes into play when developing fruit and flavor preparations.

Fruits of your flavor

Consider processing and ingredient interactions just as carefully when adding fruit and flavor systems to yogurt as when working with the other ingredients.

Joseph Kuo, product manager of cultured/fluid dairy products, Sensient Flavors, Inc., Fenton, MO, reminds us that most flavored-yogurt manufacturers approach flavoring their products holistically. They choose a combined fruit, flavor and color system as the general fruit and flavor base, which takes much of the burden off the yogurt manufacturer, and also helps adjust for variations in fruit quality. For example, yogurts with whole chunks of fruit require fruit pieces that are sturdy enough to withstand equipment and agitation, so they sometimes must incorporate relatively unripe fruit. To make up for any lack of bright berry flavor or color, a multifaceted fruit base that includes compensating flavors and colors — and perhaps even a dose of sweetener — goes a long way.

When making yogurts containing either fruit pieces or a flavored puree, achieving a consistent white-mass to fruit-prep ratio during production is challenging. "Say that you're using 88% white mass and 12% fruit prep by volume. If that fluctuates a lot — if some cups get 16% fruit and other cups get 8% — then the consumer will not be happy," Kuo says. In addition to choosing an effective stabilizer, pay close mind to equipment and make sure that the viscosity of the fruit prep meters evenly and consistently.

Because of the deleterious effects that fruit preps' solids content, added sugar and flavor compounds may have on cultures, these enter the yogurt mix after fermentation and cooling of the white mass, and before filling. Additionally, fermentation takes place under temperatures high enough to evaporate more volatile, usually water-soluble flavor compounds in the prep — particularly the natural ones.

The amount of fat in yogurt affects flavor choice, too. Marie Cummings, senior flavor technologist, David Michael & Co., Philadelphia, notes that flavor release is sharper and quicker in a nonfat system — and most yogurts are nonfat. So bear this in mind and revise the flavor profile accordingly. A fat-soluble system for a nonfat formulation should be combined with an emulsion system to ensure even distribution.

Fruit preps can benefit from at least some degree of viscosifying, but bear in mind that the line between a watery fruit prep and a thick one can be tricky to master. Modified starches help, and their relatively low costs can't be beat. However, Cummings cautions that certain stabilizers, such as some cook-up starches, are notorious for masking flavors. When combined with pectin or gums, though, she notes that, "these same starches help reduce some of the yogurt/fruit interactions that may occur in fruit-on-the-bottom or nonfat yogurts containing fruit preps. Using blends of stabilizers helps minimize the undesirable interactions and aids in presenting a cleaner flavor release."

|

To satisfy children's demand for wildly flavored portable yogurts or cookie-bit yogurt mix-ins, labeling concerns and visual clarity take a back seat. Kids' sensitive palates favor sweet over sour. Since yogurt is sour, flavoring becomes even more important. Kuo notes that yogurt manufacturers can address the tartness issue by cutting fermentation at a higher pH and using milder cultures that yield less acid. Strategically chosen fruits, flavors and sweeteners added to the fruit prep itself will achieve the expected result.

And what about nutraceuticals? As Cummings notes, "Bitterness-masking agents and sweetener enhancers seem to be key in masking some of the nutraceuticals." She also has seen flavor encapsulation succeed in masking vitamins and soy.

Flavors also can enhance the richness of low- and nonfat yogurts, and Kuo mentions fat-mimetic flavors. These fat-based and fat-soluble systems, which can support any flavor, from kiwi to cappuccino, coat the tongue to create the illusion of creaminess and richness, yet need only be used at low levels, contributing a negligible amount of fat and fat calories.

On the sweet side

In the United States, we prefer tipping the sweet-to-tart balance toward the sweet end of the scale. But what's the most effective way to satisfy our nation's collective sweet tooth when making yogurt?

Not surprisingly, Michael vom Dorp, dairy specialist, Cerestar's Food Application Centre, Kresfeld, Germany, notes that it's more than just a matter of choosing the sweetener you like best. There's a limiting factor in the cultures themselves, which are sensitive to osmotic pressure; too much sweetener in the white mass inhibits fermentation.

Since the white mass undergoes pasteurization, one might fear high temperatures would caramelize reducing sugars. Fortunately, vom Dorp says this is rarely a concern, as pasteurization time and temperature are usually calculated to avoid browning problems. However, E. Ann Nation, technical services, corn processing, Archer Daniels Midland Co. (ADM), Decatur, IL, notes that pasteurization temperatures may pose a threat to the stability of some artificial sweeteners, such as aspartame.

Crystallization generally is not a problem, either. Per vom Dorp, "You can say that the overall sweetness of the yogurt is about 14% sugar — not much more." The major sweeteners are fructose and dextrose derived from corn and, in addition, some sucrose. The quantity and quality of these sweeteners, for the most part, precludes any threat of crystallization. More commonly, grittiness may occur in frozen yogurts, but as Nation says, that, too, generally results less from sweetener crystallization than from actual ice crystals. Sandiness, or lactose crystallization, also can occur due to a lack of proper balance of NFDM ingredients.

Otherwise, the biggest concern in sweetening yogurt may simply be choosing from among the sweetener options. The flavor has some bearing on this choice. Cummings notes that you need to balance the sweetness profile with the flavor notes because consumers should be able to identify that flavor as soon as it hits their taste buds. Thus, consider individual sweeteners' intensity curves. "Fructose tends to peak and fall at the beginning of tasting a sample. Sugar will take a little longer to begin to peak, and has more of a bell-shaped curve with its peak in the middle of the profile. Artificial sweeteners take even longer than sugar to begin to peak and generally have a lingering effect, or aftertaste," she says.

Depending on the label, you can opt for a blend of HFCS with straight sucrose and other syrups. Fruit-juice concentrate also appears frequently on yogurt labels, not surprisingly, given its natural and healthful image. However, high levels of fruit-juice concentrate can contribute a bitter edge to the yogurt's taste, so manufacturers must either lower the amount of concentrate and settle for a mild sweetness or supplement the concentrate with other sweeteners, frequently honey. Honey (sometimes in conjunction with juice concentrates or maple syrup) signals that the product is naturally sweetened, often with a pronounced honey taste. Generally, a minimum of 2% honey will achieve this effect.

Nation notes that some sweeteners, notably HFCS and maltodextrin, also can modify a yogurt's texture as well as flavor. Maltodextrins also may function as fat mimetics.

While many of today's ingredients and processes might be unfamiliar to Metchnikoff, I think he'd still be pleased with the results.

Kimberly Decker, a California-based technical writer, has a bachelor's degree in consumer food science with a minor in English from the University of California-Davis. She lives in the San Francisco Bay area, and enjoys cooking and eating food in addition to writing about it.

• Photo: National Starch & Chemical Company

• Photo: North American Blueberry Council

• Photo: Kerry Ingredients

© 2001 by Weeks Publishing Company

Weeks Publishing Company

3400 Dundee Rd. Suite #100

Northbrook, IL 60062

Phone: 847-559-0385

Fax: 847-559-0389

Source: Food Product Design