The Sterilizing Power of Light

By Judy Rice, Contributing Writer

Table of Contents

Absorbing the Light

Inline Sterilization

Three-pronged Attack on Food Contamination

Ultraviolet (UV) light technologies are making progress as safety tools for the food and beverage industries. A glowing example of a company striving for commercial UV application is California Day-Fresh Foods, Inc. (CD-FF), a subsidiary of Chiquita Brands International.

In May, the Glendora, CA-based processor of refrigerated fruit and vegetable juices submitted a petition to the Food and Drug Administration for use of a UV light processing unit manufactured by Salcor Inc. (Fallbrook, CA). California Day-Fresh is hoping for a response from FDA by year's end.

The processor produces fresh juice products under the Naked Juice and Ferraro's brand names. By using their Light Processed System in conjunction with the processor's Hazard Analysis and Critical Control Points (HACCP) program, California Day-Fresh is confident that levels of harmful bacteria can be kept well within the strict limits prescribed by FDA's fresh, non-pasteurized juice regulations.

In addition, the UV treatment will increase product shelf life, enabling the company to expand its market areas. California Day-Fresh Foods' public relations manager Heidi Meinholz reports that use of the UV light treatment may as much as double refrigerated shelf life of vegetable juices.

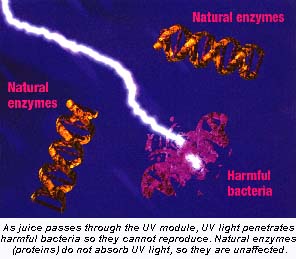

Absorbing the Light

In operation, the Salcor modular unit completely exposes the juice to UV light as the product tumbles through transparent Teflon-coiled tubing. By absorbing the UV light, the harmful bacteria's DNA strands are fused together, thus preventing the bacteria from reproducing. The juice then immediately is cold-filled into plastic bottles, which have been manufactured via the thermal blow molding process.

Dr. James Cruver, president and CEO of Salcor Inc., tells VerticalNet that pilot trials of the UV light system have been conducted with several juice processors, and that the unit also has potential application for a range of other liquid products. "In addition to the CD-FF unit installation, we also are installing units at the National Food Processors Association's National Food Labs in Dublin, CA; at the Illinois Institute of Technology's National Center for Food Safety & Technology in Summit-Argo, IL; and at the FDA's Apple Hill testing labs in Placerville, CA. Processors of liquid products will be able to do test runs to gauge the technology's efficacy and flow rates for their products," said Cruver.

Tetra Rex Filling Systems, a Tetra Pak Inc. operation, also is embracing UV light sterilization technology. The Buffalo Grove, IL-based company recently introduced the TR/18 ESL gabletop carton filler for the dairy and juice industries. The cartons are protected against harmful micro-organisms — including Listeria, E. coli, Salmonella, yeast and mold — by a sophisticated, multiple sterilization system. The sterilization mechanisms include a 3% hydrogen peroxide vapor system, patented UV light process, hot air dryer/remover, sterile air system, aseptic diaphragm valves and self-contained automatic cleaning. Dairy and juice drinks packaged on the TR/18 ESL can have estimated shelf life up to 90 days.

As Ron Swank, Tetra Rex hygiene specialist, comments, "Dairy and juice products are under constant attack from dangerous contamination-causing agents. The TR/18 ESL was designed to provide a self-contained 'clean room' environment, blocking out impurities."

Inline Sterilization

Another technology, the PureBright sterilization system developed by PurePulse Technologies, a subsidiary of Maxwell Technologies (San Diego, CA), utilizes intense flashes of light in the UV to NIR (near infrared) range to kill bacteria, spores and viruses and to deactivate organisms on the surfaces of foods and packages. Currently, PureBright applications are mainly in the medical and pharmaceutical areas.

But according to director of marketing, Roy Wallen, the online, continuous system can be used in a variety of other applications. For example, Wallen reports there has been interest expressed in applying PureBright to inhibit mold formation on the interiors of film packaging for cheese.

The company points out that light sterilization technologies have certain advantages over more traditional techniques. There are no residues as can occur with chemical sterilization, and no degradation of the organoleptic properties of foods and beverages as can occur with heat sterilization.

Wallen adds, "Our Broad Spectrum Pulsed Light (BSPL) method is unique in accomplishing complete kills of micro-organisms. Unlike many other UV methods, we have developed the ability to assure total inactivation of micro-organisms, including viruses."

Three-pronged Attack on Food Contamination

CVP Packaging Systems (Downers Grove, IL) also has been delving into UV light technologies. CVP provides a variety of extended-shelf-life packaging solutions for fresh and refrigerated food products. And through its U.K. strategic ally, Holmes Newman, the company also offers two shelf-life-extending food decontamination technologies, both based on UV light. One technology is called SelectUV and is specifically designed for treatment of bulk foods. The other, called Fresh Safe, is more suitable for individually packaged products.

Holmes Newman operates an R&D Center in San Diego. Senior partner Dr. Paul Newman explained, "Fresh Safe is a three-pronged attack on food contamination. First it uses short-wave UV light to attack bacteria, fungi and yeast on food surfaces. Second, it uses automated sanitation systems to clean conveyors and other processing equipment. And third, it locks contaminants out of the packaging environment.

"In Holland," notes Newman, "a company called Easi-Foods is using the Fresh Safe technology in a revolutionary ready-to-eat, home-delivered foods concept. The idea is that consumers can call on the phone or even dial up on the Internet to order prepackaged fresh food components. The consumer could order a package of fresh chopped onions, tomatoes, raw or precooked meat of choice, whatever. Then proceed to prepare and combine these components in whatever manner desired. Basically, the consumer is getting a UV-sterilized, prepackaged buffet."

Indeed, UV technologies continue to make inroads as effective tools for food and beverage industry safety.

For more information:

Salcor Inc., Dr. James Cruver, Tel: 760-731-0745.

Tetra Rex, Dave Perry, Tel: 847-465-7000.

PurePulse Technologies, Roy Wallen, Tel: 858-503-5054.

CVP Packaging Systems, Dr. Paul Newman, Tel: 800-422-4720 or 011-44-183-755-186.