Coperion And Coperion K-Tron To Exhibit At The International Dairy Show 2015

Pitman, NJ, USA - At this year’s International Dairy Show, Coperion and Coperion K-Tron will exhibit in booth 8355 at McCormick Place, Chicago, IL. Visitors to the booth will see a WYK Two-Way Diverter Valve, a ZRD Hygienic Rotary Valve and a P30 Sanitary Vacuum Sequencing Central Receiver.

Coperion and Coperion K-Tron are proud to be finalists in food safety and packaging categories for the International Dairy Association’s Innovations Award. The WYK Diverter Valve, known for its innovative design, has been nominated for the competition for its substantial achievements in performance and having shown significant advancement in its application.

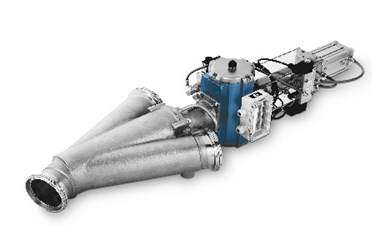

WYK Two-Way-Diverter Valve

The WYK Two-Way Diverter Valve is ideally suited for inline material handling of hygienic and difficult to handle powders, such as whey powder, lactose, dried milk powders and infant formula. This valve can be used in pneumatic conveying systems, in order to divert transfer of the powder to different locations. The fully automatic CIP cleaning design permits complete purging of all product residues after the automatic cleaning process. Due to a unique retractable rotor assembly, the rotor can be pulled slightly out of the housing towards the rear of the valve, thus allowing the cleaning solution to rinse all product contact surfaces within the valve. In addition, specialty purge openings in the actuator plate enable an intense rinsing flow and complete discharge of the rinsing effluent.

ZRD Hygienic Rotary Valve – USDA approved, easy to clean

Coperion’s ZRD sanitary rotary valves have been approved by the United States Department of Agriculture (USDA) following certification in compliance with the USDA Dairy Grading Branch. Already designed in accordance with the engineering and design guidelines of the EHEDG (European Hygienic Engineering & Design Group), these sanitary rotary valves also meet the current, strict requirements governing application in the USA. The valves can be used in the food, pharmaceuticals and chemical industries for applications demanding even the highest degree of hygiene and cleanliness. In addition, they are distinguished by their extreme reliability in operation. As these rotary valves can be readily inspected and also cleaned quickly and thoroughly, they are ideal for applications involving frequent changeovers from one product to another and/or for processing products with adhesive tendencies. Parameters such as particle size, cohesion and adhesion influence the flow properties of bulk materials and therefore also the correct design and layout of bulk material handling components. The ZRD Hygienic Rotary Valve offers an extra-large inlet for high throughputs and is suitable for pneumatic conveying up at up to 1.5 bar (g)/21 psi.

The sanitary versions of the ZRD rotary valves are used in pneumatic conveying systems and for the discharge of powdered and granular materials. The certified versions of the ZRD series of rotary valves are equipped with the innovative and service-proven FXS (Full Access System), which enables easy withdrawal of the rotor, as both end plates can be swung out to an angle of more than 90°, making the interior of the rotary valve fully accessible. The withdrawn rotor can then be readily detached from the end plate.

P30 Vacuum Sequencing Central Receiver – Sanitary Pneumatic Conveying

The Coperion K-Tron P-Series receivers provide a sanitary, custom solution for difficult conveying applications. The sanitary design is perfect for applications in the food and pharmaceutical industries. The P-Series receivers are constructed of stainless steel and features include steep cone angles to ensure excellent discharge and band clamps for quick disassembly. With the choice of various discharge valve types (powered flap and active driven butterfly valves) the P30 can be used for conveying only applications such as hopper loading, as well as loss-in-weight feeder refill applications, where the receiver is not always emptied completely. Conveying rates vary depending on model, product characteristics and conveying distances. Typical materials include flakes, free-flowing to poorly flowing powders, and materials requiring gentle conveying.

Source: Coperion GmbH